Home : SMR : SMART Technology : SMART Key Data and Attractions

SMART Key Data and Attractions

Key Data

| Reactor Type | Integral PWR |

|---|---|

| Thermal capacity | 330MW(t) |

| Electrical capacity | 100MW(e) |

| Desalination | 40,000 ton/day |

| Capacity factor | 90% |

| Design Life | 60 years |

| Dimensions of Reactor Vessel | Height 18.5m, Diameter 5.99m |

| Fuel | < 5.0 w/o enriched UO2 pellet, 17x17 square FA |

| Refueling Cycle | 36 months |

| Core Damage Frequency | < 5×10-7/RY |

| Plant Footprint | 90,000㎡ |

| Residual Heat Removal System | Passive |

Attractions

1. Harmonizing Innovative Concept and Proven Technologies for Licensing and Market Acceptability

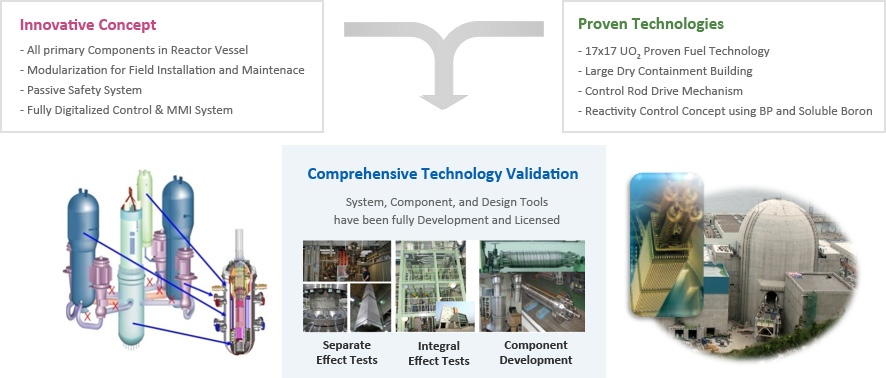

SMART basically adopted proven technologies of existing PWR such as 17x17 UO2 fuel technology, large dry containment building, control rod drive mechanism, and reactivity control concept using BP (burnable poison) and soluble boron. Harmonizing these proven technologies with innovative concept of integrated design, modularized vessel, passive system, and fully digitalized control system & MMIS, SMART has achieved comprehensive technology validation.

Harmonizing Innovative Concept and Proven Technologies

for Licensing and Market Acceptability

2. Enhanced Safety

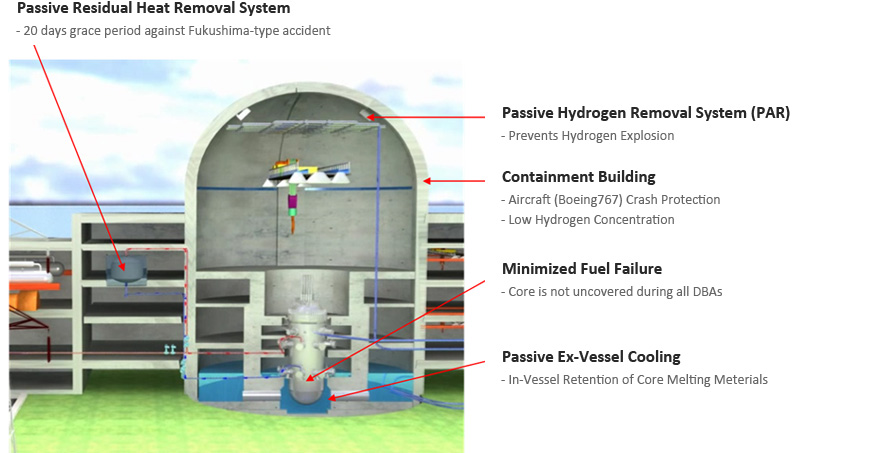

SMART has been designed with several enhanced safety features. Passive residual heat removal system can secure 3 weeks of grace period against Fukushima-type accident. Passive hydrogen removal system can prevent hydrogen explosion. Large containment building can secure low hydrogen concentration and aircraft crash proof. SMART minimized fuel failure and adopted passive ex-vessel cooling features to prevent vessel failure.

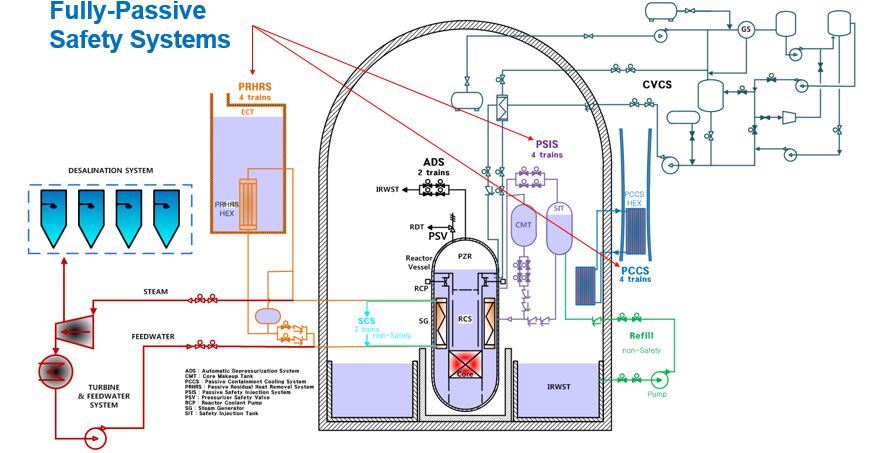

3. Fully-Passive Safety Systems

SMART features four (4) reliable full-passive systems: four (4) trains of Passive Containment Cooling System (PCCS), Passive Residual Heat Removal System (PRHRS) which removes residual heat for more than 20 days, four (4) trains of Passive Safety Injection System (PSIS) which provides emergency core cooling in LOCA (Loss-Of-Coolant Accident), and Passive Hydrogen Removal System (PHRS) which prevents hydrogen explosion.

- About Us

- About us Location & Contact

- SMR

- SMART Technology - Development History - Design - Technology Validation - Standard Design Approval(SDA) - Implementation after Fukushima - Fields of SMART Application - SMART Key Data and Attractions SMART Projects - SMART Partnership with KSA - Commercialization with KSA

- Dismantling & Decommissioning

-

Management of radioactive and

hazardous waste Decommissioning of nuclear facilities Engineering & Consulting - Training Services

- Engineering & Consulting

-

International Employee

Deployment & Staffing - News